-

Email info@maxpet.in

-

Call Now +91 9980978900

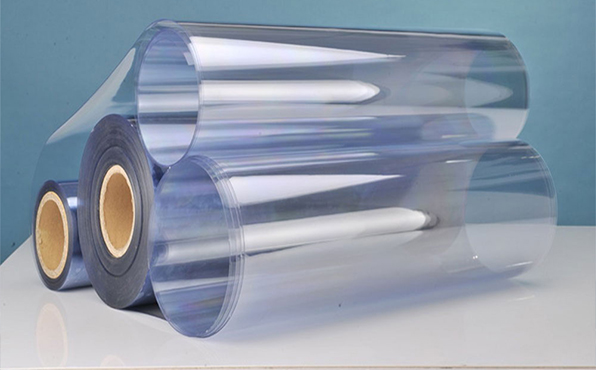

| Material | PET |

| Thickness | 150 Micron - 1200 Micron |

|---|---|

| Color | Colored,Transparent & Opaque |

| Usage/Application | Packaging |

At MAXPET, We focus on the manufacturing and supply of PET sheets in both clear and colored forms to meet any specific application requirements. Whether you’re in need of packaging solutions for consumer products, pharmaceuticals, food & beverages, or engineering items, our PET sheets provide superior protection and strength compared to alternatives like PVC or HIPS.

We are the leading service provider in India for PET Sheet used for Food packaging, Pharmaceutical packaging, Anti-static packaging and Printing applications.

MAXPET specializes in manufacturing and supply of PET (Polyethylene Terephthalate) sheets in both clear and colored forms to suit any specific application requirements.

With an excellent characteristic of vacuum & pressure forming, transparency, high color, impact resistance, and chemical resistance, PET Sheet is suited for making packaging material for Stationaries, Toys, Tools, Gifts, and other large variety of custom merchandise.

PET doesn't transfer any chemicals to the product it comes in contact with, which makes it an ideal & economical solution for packaging of food products. A-PET & rPET sheets are produced by non-toxic formula which ensures 100% sanitation of packaged items. Therefore, it is highly suitable for packaging of a large variety of food products such as Chocolates, Fruits, Eggs, Cakes, Candies and sealed Water cups etc.

The PET sheet has excellent transparency, high gloss and non-whitening characteristics, suitable for the customized packaging of Toys, Gifts, Clothes, and Cosmetics etc. PET Packaging suitably enhances the optical characteristics of the packaged items and delivers ideal results for product presentation.

Pet sheet has outstanding transparency and static resistance characteristics also support direct UV offset printing and screen printing making it an ideal choice for printing of items such as sports cards, collection cards and various other custom-printed consumer Product Boxes.

Pet sheet equipped with an outstanding static resistance characteristic can be easily vacuum formed and thus it is also a highly suitable & recommended option for general packaging of electronic items like cell phones, tablets, notebooks and various other electronics accessories and spare parts etc.

With the same excellent characteristics of vacuum formation, transparency, high-gloss, impact resistance and chemical resistance PET also highly suitable for packaging of medicines, ampoules and vials etc.

Excellent transparency, appearance, outstanding vacuuming & high-frequency sealing features make Maxpet Sheets a more suitable option for sealed packages of a variety of end-consumer products.